Temp.tabell

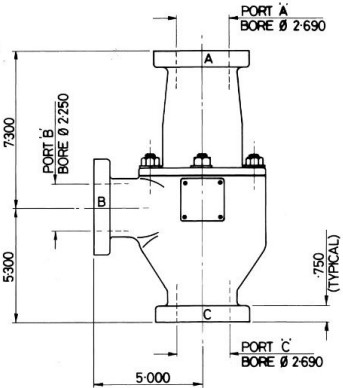

DN50 20100D med flens

Modell 20100D er en 3-veis TCV med flenser i diameter DN50. Modell 20100D har et lavere trykkfall sammenlignet med modell B i DN50. 20 kg.

- Parameter

- Verdi

- Kode

- Lekkehull Diameter

- Maksimalt Trykk: 10 Barg

- Flowkoeffisient Kv: 85

- Flowkoeffisient Cv: 98

- Vekt (omtrentlig): 20 kg

TCV-en er en direktevirkende, internfølsom, selvvirkende 2- eller 3-veis temperaturreguleringsventil. Reguleringen skjer automatisk som et resultat av temperaturen til væsken som strømmer gjennom ventilen.

Før installasjon

- Ved mottak bør ventilen sjekkes for skade som kan ha oppstått under frakt. Alle AMOT-ventiler har navneskilt, som er stemplet med modellnummer og serienummer.

- Før installasjon må du forsikre deg om at ventilen er egnet for formålet, ved å sjekke temperatur-, trykk- og materialparametere, samt eventuelle spesielle godkjenningskrav. Kontroller at de tiltenkte rørtilkoblingene er egnet for applikasjonen.

- Sjekk at ventilstørrelsen er valgt i samsvar med den forventede strømningshastigheten gjennom ventilen. For å opprettholde god temperaturregulering bør trykkfallet over ventilen ligge i området 0,14 til 0,5 bar (2 til 7 psi).

- Hvis ventilen skal monteres på et høyt punkt i systemet, bør systemet ventileres for å hindre fanget luft rundt temperaturfølerne.

- For optimal temperaturregulering bør systemet utformes slik at elementet er i midtposisjon under nominelle forhold. For å oppnå dette kan det være nødvendig å balansere væskestrømmen ved å sette inn en åpning i bypass-kretsen.

Montering av ventilen

Ventilen kan monteres i hvilken som helst posisjon, men bør festes skikkelig og ikke utsettes for overdreven belastning. Sørg for at rørene er i korrekt posisjon for å unngå overbelastning av ventilhuset.

Oppstart:

- Ved installasjon og oppstart av systemet bør alle deler av kretsen kontrolleres nøye for å sikre korrekt ytelse.

- Systemtemperatur skal ende opp svært nær ventilens setpunkt, gitt at flowen er iht ventilens oppgitte kapasitet.

- Hvis systemtemperatur avviker er med mer enn 2,7°C (5°F) fra settemperatur, anbefales det å diagnostisere årsaken til avviket.

- Hvis systemtemperatur avviker fra settemperatur med mer enn 5,5°C (10°F) bør årsaken lokaliseres og feilen rettes opp.

Drift: Ventilen er helt automatisk i drift og krever ikke brukerintervensjon for å fungere.

Vedlikehold: Ventilen må fjernes fra rørsystemet før noe vedlikehold kan gjøres på ventilen.

Demontering av ventilen

- Fjern husmuttere (11) og del ventilen. Fjern det nedre huset (2), og vær forsiktig så du ikke skader elementene. Fjern og kast huspakningen (3) og sørg for at eventuelle rester av pakningen fjernes fra husets matingflater.

- Trekk ganske enkelt ut elementet fra det øvre huset.

- Inspiser ventilsetet for slitasje eller skade. Hvis nødvendig, bytt ventilsete (5), fjern ved å skru ut skrue (14).

Montering av ventilen

- Smør pakningen (3) rikelig med et godt kvalitets petroleumsgrease, la det trekke inn.

- Hvis ventilsetet ble byttet, sett på plass skruen med Loctite 2400 låsekomponent (EJ).

- Smør moderat og strekk den nye 'O'-ringen (7) og plasser den i det øvre huset (1). Plasser 'O'-ringen konsentrisk for å hjelpe med montering av elementet.

- Sett elementet inn i det øvre huset, og vær forsiktig så du ikke skader 'O'-ringen.

- Plasser den smurte pakningen på det øvre husets leddflate (1). Sett det nedre huset (2) over det øvre huset, fest med muttere (11) og skiver (10), og bruk Loctite 2400 låsekomponent (EJ).

Se datablad for komplett informasjon