Features and Benefits:

- Corrosion-resistant, Gulfproofed finish

- One moving part for easy to maintenance

- Wide operating pressure range

- Field proven

Typical applications:

- Pneumatic control panels

- First-out indication

- Safety sequencing systems

- Fail safe systems

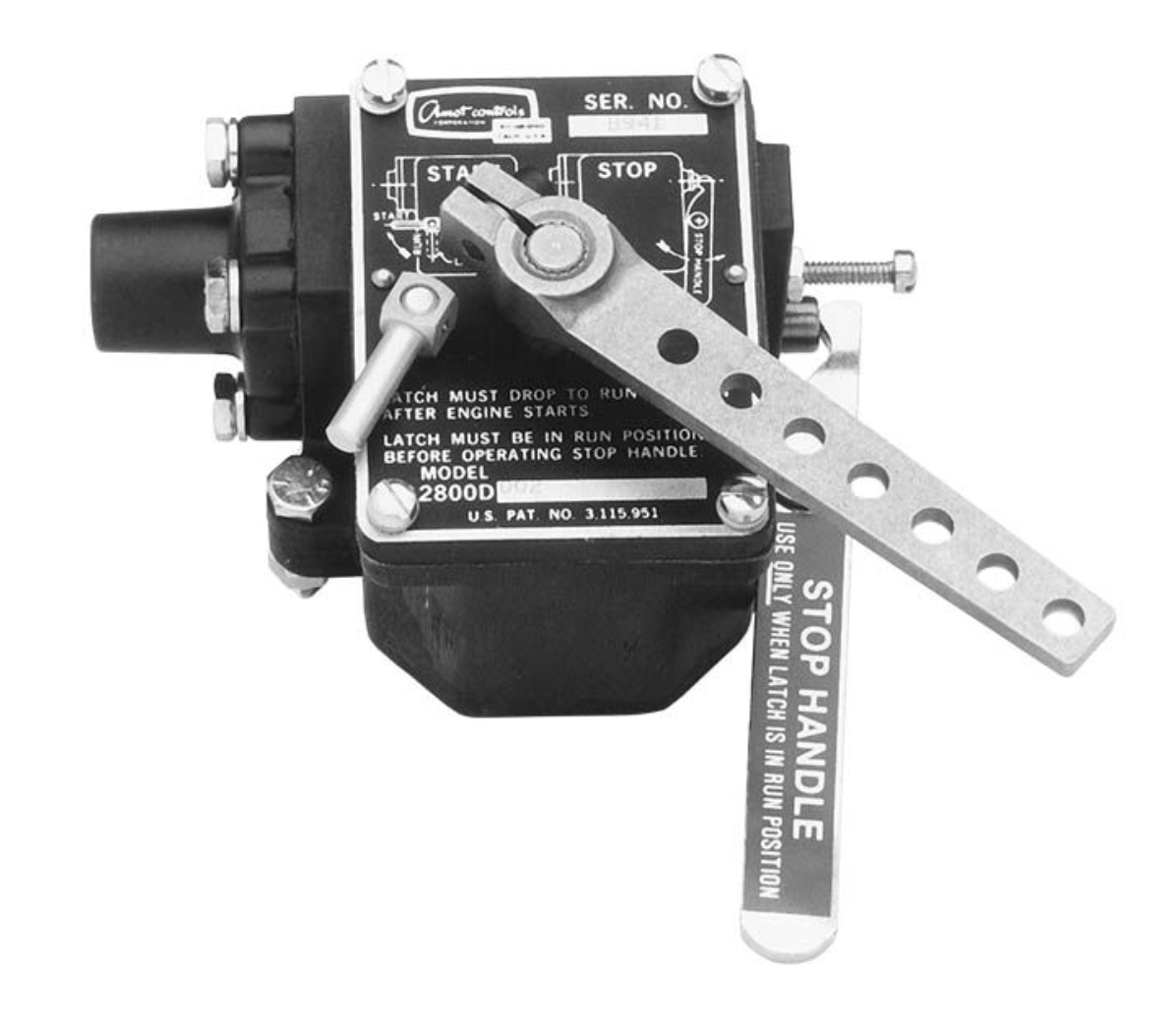

2400 INDICATING RELAY

Model 2400D pneumatic indicating relays can be used in many different ways in control and warning systems but their most common application is for tripping a safety systems and indicating the cause. Its robust design can withstand rigorous conditions experienced in diesel and gas operating environments and is proven to be highly reliable in turbine pump and other demanding process applications.

Usually one 2400D relay is connected to each condition sensing device. The sensing devices are normally closed 2 or 3 way valves which detect undesirable temperatures, pressures, vibration, liquid levels, etc. Sensing valves are connected to the TRIP port in each relay, and pressure is introduced at the IN Port. If the particular parameter is in a "Run" or satisfied condition, and the sensing valve is closed, pressure will feed through the internal orifice to the large end of the piston and force it into the "Green" or safe position. Pressure is also directed through to the OUT port which is normally piped to the IN port of the next relay. When a fault condition arises, the valve sensing that condition opens, causing a loss of pressure at the large end of the piston and allowing pressure on the small end to move the piston to the "Red" or tripped position.