Typical applications:

- Monitors pressure or temperature on rotating machinery in hazardous and industrial applications

Features and Benefits:

- Entirely mechanical - no external power required

- Snap acting - immediate shutdown upon sensing loss of oil pressure below setpoint

- Easy installation and operation - reset latch emergency stop and multi-positional reset lever

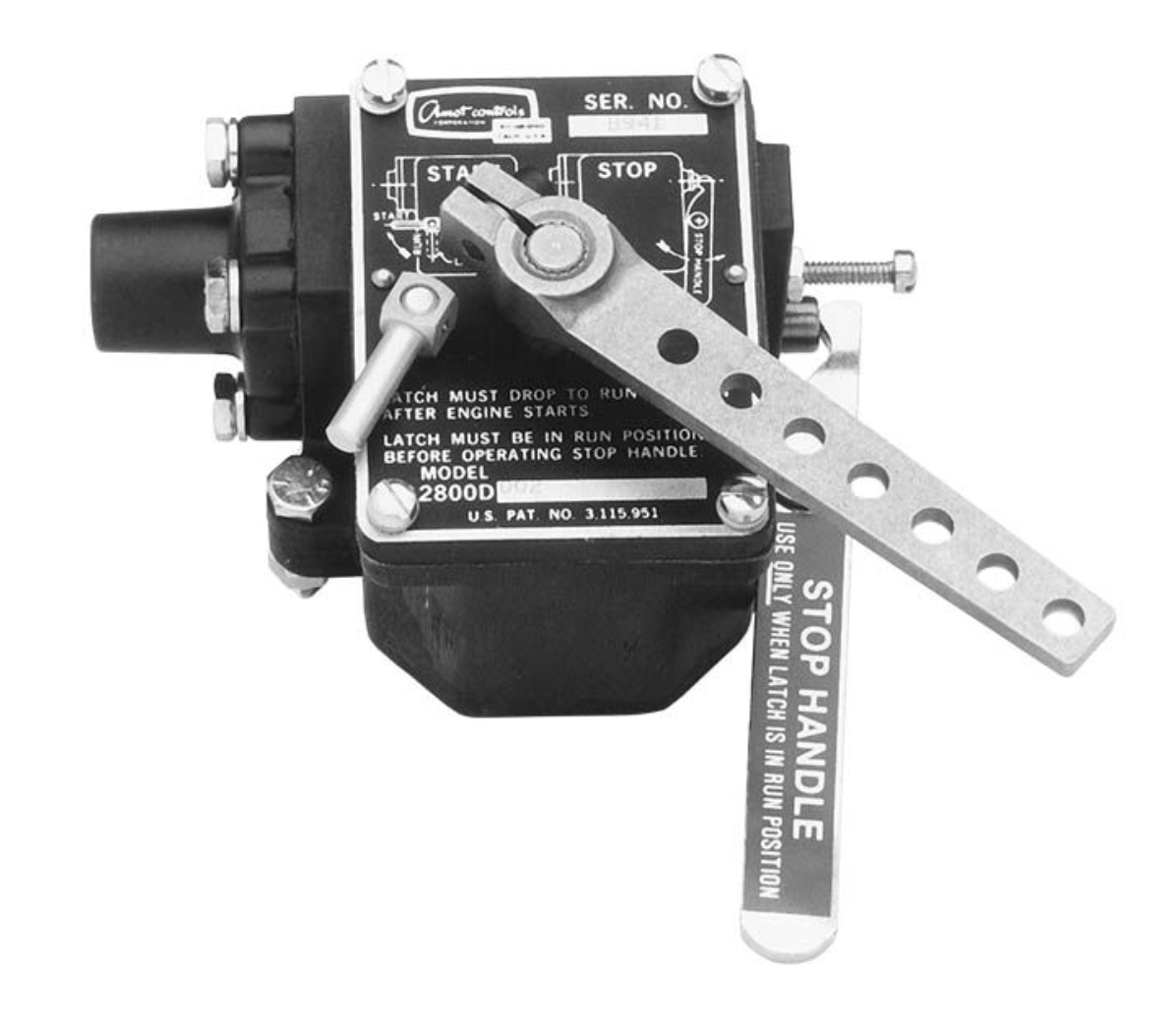

2800 SAFETY CONTROL

Model 2800 fuel rack actuator is a safety shutdown device which senses oil pressure or other control pressure. This device is typically connected to an engine fuel rack governor or fuel pump stop lever and should a loss or drop in oil pressure occur below the set point, it will trip immediately.

Model 2800 may be used alone or as the engine shutdown component in an engine monitoring system. It also can be coupled with a wide array of devices for monitoring pressures, temperatures or other variables on rotating machinery, or can operate as a stand-alone oil pressure sensor. Model 2800 is a snap acting device monitoring low lubricating oil pressure or other control pressure. An emergency stop handle and a trip pressure adjusting screw are standard. Factory set to trip at 0.7 bar (10 psi) and field adjustable, from 0.35 - 2.8 bar (5 - 40 psi). A trip lever is installed on a splined shaft, and can be clamped in any of 36 radial positions to facilitate installation in most applications. The lever permits mechanical linkage between the tripping unit and the engine governor control, fuel pump stop lever or other mechanism. Predrilled holes give a wide range of connection options. A standard reset latch is supplied.

The reset latch locks the trip lever in the “run” position until oil pressure is up to normal operating pressure, then the latch releases thus arming the device. In normal condition, the 2800 is in open position and is being held open under the system pressure. When the system pressure drops below the factory set trip pressure of 0.7 bar (10 psi), the handle rotates 90° clockwise from its position in the open condition and closes the valve. In order to reopen the valve, the handle is moved to open the valve and the reset latch is engaged, which will hold the handle while the system is pressuring. The reset latch will be released when it reaches the reset latch release pressure of 1.8 bar (26 psi) and model 2800 will be open and working under the system pressure.