Features and Benefits:

- Provides early wearning of problems - avoids high cost bearing failures

- Used with oil, air or gas

- Instand response to excessive bearing temperatures

- Compact design - easy, low cost installation

- Minimal maintenance - low cost of ownership

Typical applications:

- Accurate and reliable in engines used for gas compression, power generation, pipeline, marine and general industrial service.

- Monitors bearings, shafts and other moving parts for unsafe high temperature levels

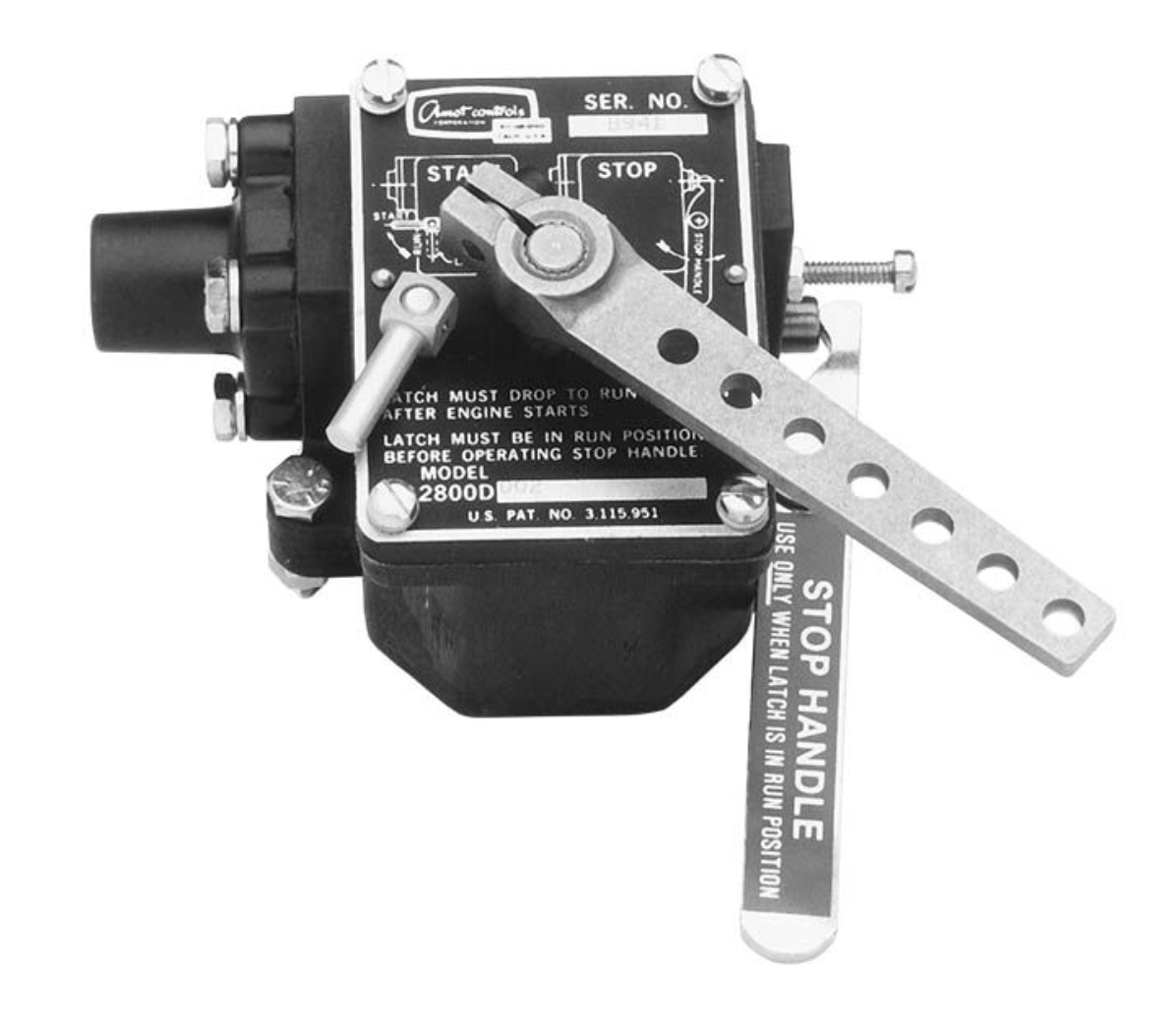

4102 TEMPERATURE DETECTOR FOR MOVING BEARINGS

AMOT Model 4102D & 4102J Temperature Valves and Model 4102M Miniature Temperature Valves are ideal for use on medium and high speed engines. The valves initiate a warning or shutdown upon a sudden temperature rise in critical machine parts caused by tight, worn or out-of-round bearings, tight packing glands, cracked or broken shafts, torsional vibration, power or compressor cylinder overload, lack of lubricant flow and many other sources. The 4102M valves provide the same low cost reliability for small bearings that have been field proven by their larger counterparts (Model 4102D & 4102J) in larger stationary bearing applications. (Note: Fuse rod 6702 is a component of the 4102 product family.)

AMOT Model 4102 temperature detectors are a safety device suitable for monitoring bearing temperature. A thin film of eutectic alloy secures a spring-loaded fuse rod. When the temperature increases, the sensing end melts the alloy and the fuse rod is instantly released moving outwards. Due to their small mass, the detectors are virtually as responsive as thermocouples. Model 4102 temperature detectors do not require the impractical wiring of electrical sensors.