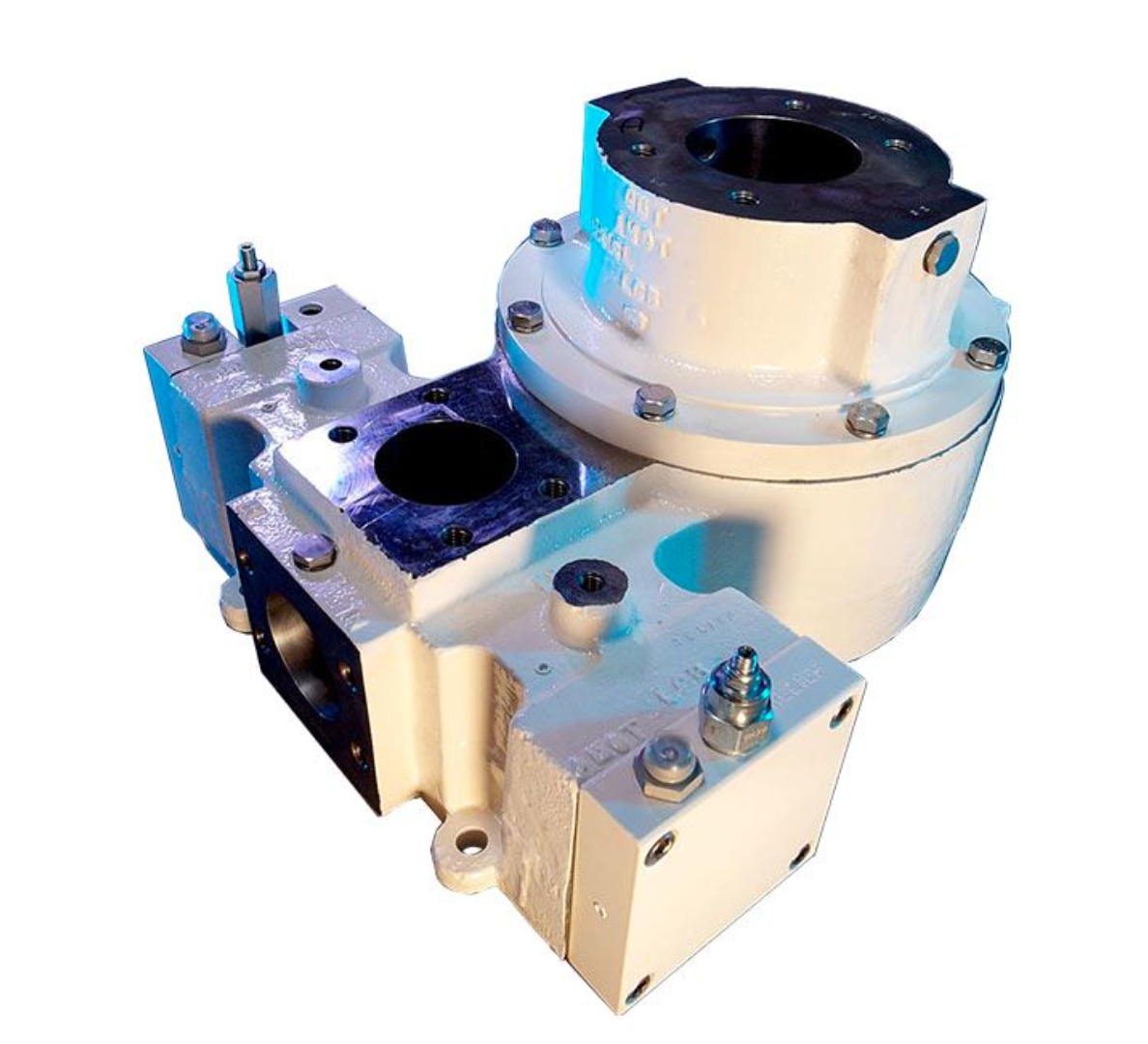

Details

- Features and Benefits: * Combined pressure, temperature and pressure relief in a single valve * Remote downstream pilot pressure regulation * 4" internally sensed 3-way temperature control valve * Integrated pressure relief valve * Carbon steel or stainless steel construction * Ports for instrumentation * Reduces installation costs (valves, piping, fittings, flanges) * Simplifies material planning * PED suitable for Group 1 & 2 liquids * ATEX II 2G Ex h IIC T6…T3 Gb X * CE

- Typical applications : A pressure and temperature regulating valve for lubricating oil on gas turbine generator sets.

4500D Temperature & Pressure control valve

The AMOT combined temperature and pressure control valve is used in applications where both temperature and pressure control are required simultaneously. It combines temperature control, pressure regulating and pressure relief into a single manifold valve, thereby reducing installation costs and simplifying material planning. The valve is designed to be mounted directly on the oil tank to reducing piping.

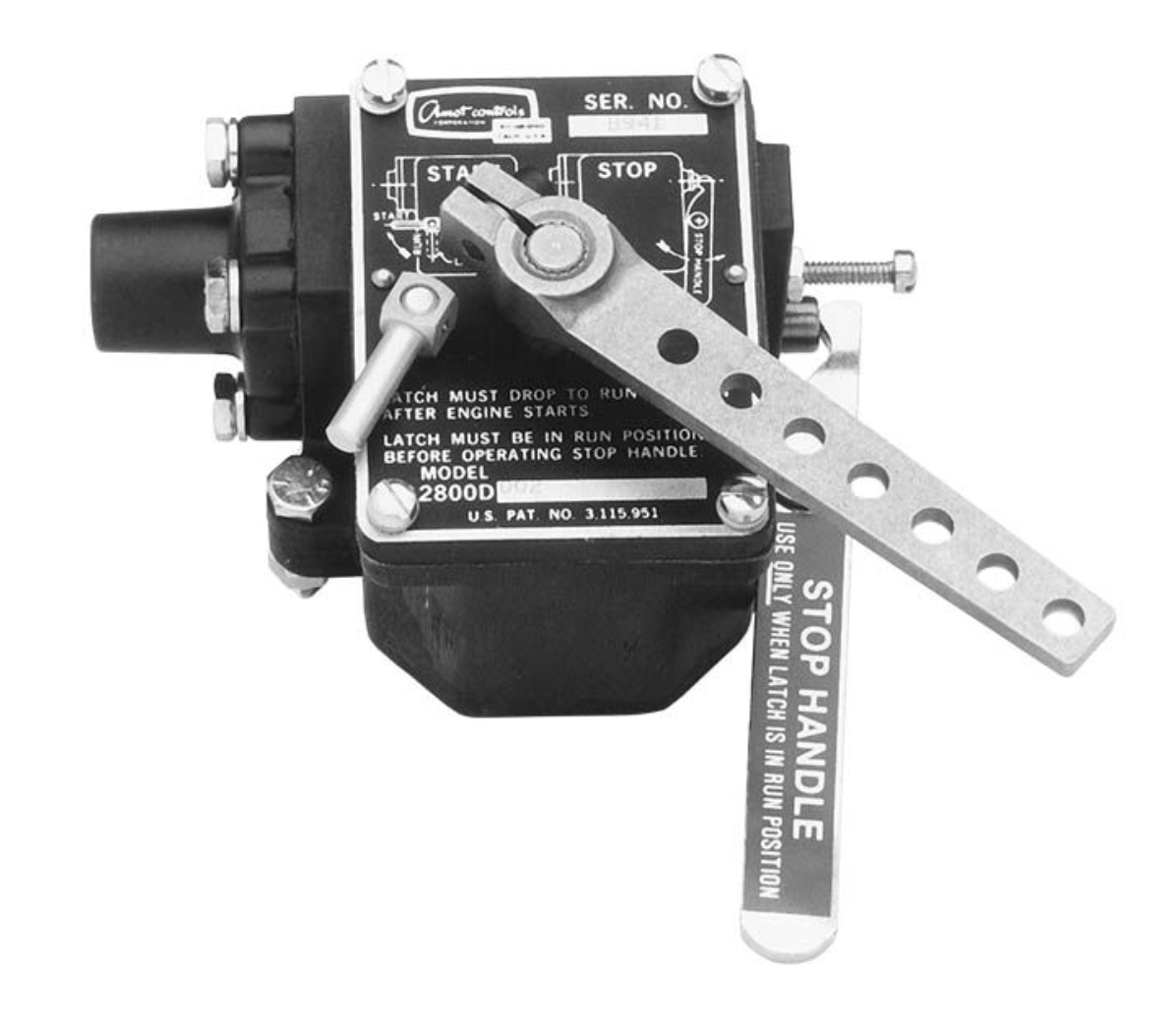

The 4500 has been specifically designed and developed by AMOT Controls as a pressure and temperature regulating valve for lubricating oil applications. Oil pressure is regulated by the pilot operated Cartridge Regulator. The pilot feed to the Regulator is taken down stream of the oil filters to sense the oil pressure. Pressure is controlled by regulating the amount of oil that is dumped through the Cartridge Regulator, back to the main reservoir.

The temperature of the oil is then controlled by the internally sensed 3-way temperature in the valve. The oil flow then split between flowing through a cooler external to the valve and an internal bypass that flows directly to the thermostatic elements. The flow through the internal bypass and cooled oil returning from the cooler are mixed and regulated by the temperature elements to the desired temperature before leaving the valve. The temperature and pressure regulated oil exits the valve and flows through the lube oil system filters before flowing to the equipment requiring lubrication.