Details

- Design features: Modular interface concept for remote control Local controls with lockable selector switch, push-buttons and indication lights LCD for status indication and programming support Non-intrusive actuator setting and control programming (in connection with magnetic limit and torque transmitter MWG) Separate mounting on wall bracket possible Motor control via reversing contactors or thyristors Automatic phase correction External 24 VDC supply (option)

- Ambient conditions: High enclosure protection High quality corrosion protection Wide ambient temperature ranges

- Interfaces: Electrical connection via AUMA plug/socket connector (optionally terminals) Cable entries in different versions FO connection for fieldbus Interfaces HART

- Interfaces and features: Control inputs with different voltages (DC/AC) Potential-free signal relays for status indication Analogue control (0/4-20 mA) Programmable stepping mode (for running time extension) Freely definable intermediate positions Process controller (PID) Fieldbus control (Profibus DP/DPV1, Profinet, Modbus RTU, Modbus TCP, HART, Foundation Fieldbus, Wireless HART) Fieldbus interface also available as component redundancy Limit and torque as analogue Signal (in connection with magnetic limit and torque transmitter

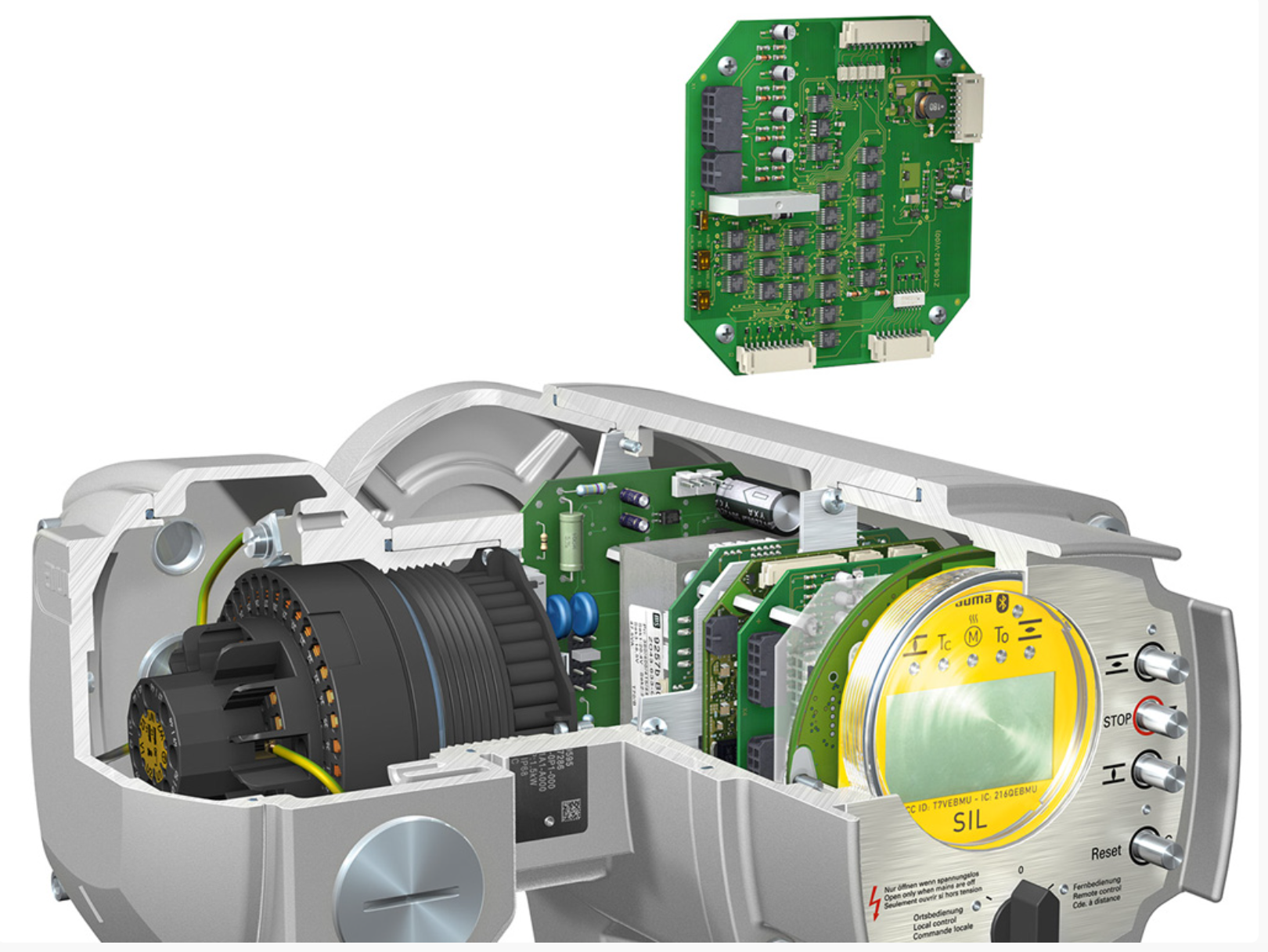

AC SIL and ACExC SIL

AUMA offers sophisticated control for premium safety requirements with AC 01.2-SIL or ACExC 01.2-SIL actuators controls. SA.2 and SQ.2 actuators combined with these actuator controls can be deployed in safety-related system systems up to SIL 3.

AC 01.2 actuator controls in SIL version are equipped with an additional SIL module designed for the execution of safety functions. In case of an emergency at the plant and when requesting a safety function, the standard logic of AC .2 is by-passed and the safety function is performed via the SIL module. Consequently, the safety function always overrules standard operation.

The highest functional safety level is ensured by the combinations of AC .2 SIL with multi-turn actuators of the SA.2 range or part-turn actuators of the SQ.2 range, certified by TÜV according to IEC 61508 (ed.2). These combinations can be used up to SIL 2 and in redundant version (e.g. 1oo2) even up to SIL 3. The comply with the latest and most demanding issue of IEC 61508 and offer superior flexibility when adapting the safety function within the respective safety instrumented system (SIS).

SA.2 and SQ.2 actuators equipped with these actuator controls have been certified by TÜV Nord. They are suitable for the following safety functions:

- Safe OPENING/CLOSING (ESD) up to SIL 2 (single-channel system) or SIL 3 (redundant system) according to IEC 61508 Ed.2

- Safe STOP up to SIL 2 (single-channel system according to IEC 61508 Ed.2)

- Safe end position feedback up to SIL 2 according to IEC 61508 Ed.2 or up to PL c according to ISO 13849 (not integral part of the certificate. A separate declaration of incorporation is available)