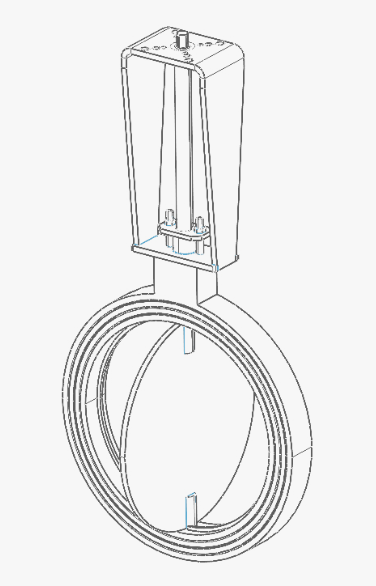

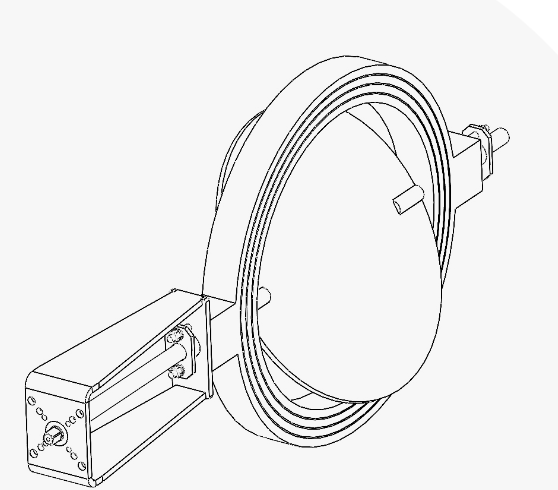

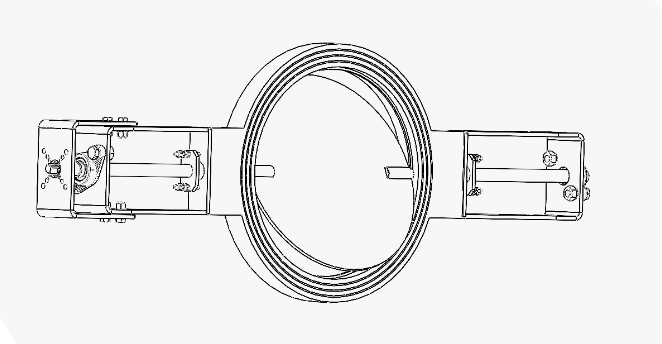

ASX-310 24V/25A Tri-Certified Self-Exciting Flameproof Alternator

The ASX-310 24VDC/25Amp Self-Exciting Flameproof Alternator is a self-excited alternator designed for use in belt driven, diesel engine applications. The ASX-310 is tri-certified for use in hazardous areas classified as ATEX/IECEx Zones 1 or 2, NEC 500 Division 2 and NEC 505 Zone 2. It is suitable for ambient temperature range -30°C to +55°C. The alternator is designed to work in applications where a battery or other external power source is not available.

Features and Benefits

- Compact high performance design

- Certified for hazardous areas classified as ATEX/IECEx Zones 1 or 2, NEC 500 Division 2 and NEC 505 Zone 2

- Self-excited, a battery is not required

- Speed signal output for overspeed shutdown

- Certified cable gland side entry on rear cover

- Rear cover can be rotated for alternate cable entry locations

- Wide choice of optional pulleys

- Suitable for offshore conditions

Application

Designed as belt driven diesel engine mounted alternator for use in hazardous areas classified as ATEX/IECEx Zones 1 or 2, NEC 500 Division 2 and NEC 505 Zone 2 applications. Suitable for a local ambient temperature range between -30°C and +55°C. Speed signal output available. Power output suitable for changing a medium sized diesel engine start battery, subject to the following limitation:

- Self-excited, for use in applications without batteries or external power source available

- The output demand not to exceed 25 amps

- This equipment must not be used for other applications without prior approval of Chalwyn

Operation

The ASX-310 Flameproof Alternator is designed to be a direct replacement for non-flameproof alternators used on diesel engines. The alternator is a self-exciting design and does not require a battery or external power source. Some adjustments to mounting brackets and belt tensioning link may be necessary. The alternator rear cover can be rotated to provide alternate cable entry positions.

In the case of fixed speed applications the pulley drive should be arranged to give a continuous alternator speed of between 5,000 rpm and 7,000 rpm. In the case of variable speed applications the pulley ratio should be selected to give an alternator speed of 2,000 to 2,500 rpm at the engine low idle. This typically equates to a normal operating alternator speed range of about 3,500 rpm to 8,000 rpm.

The maximum output demand for the ASX-310 alternator should not exceed 25 amps.