Diesel Engine Exhaust Spark Arrestors - Stainless CE224: SAA - SAB

Chalwyn stainless steel spark arrestors help mitigate the risk of fire from the ignition of flammable materials caused by spark emission from diesel engine exhaust.

They are designed to meet the requirements of the latest generations of low emission diesel engines (NRMM stage III A / B, stage IV and V; equivalent US Tier 3 & 4 : Euro 5 and 6 (other harmonised standards) and engines fitted with exhaust treatment devices such as DOC (catalysts) DPF (particulate filters) and SCR (NOx abatement) Post 2014.

Operating Principle

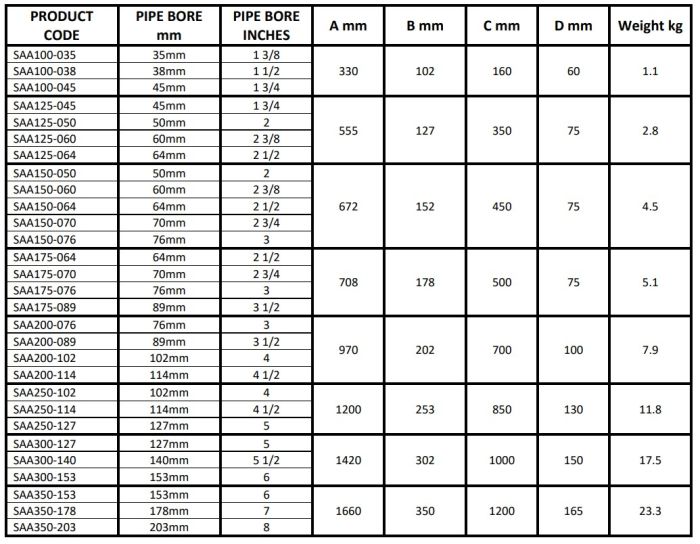

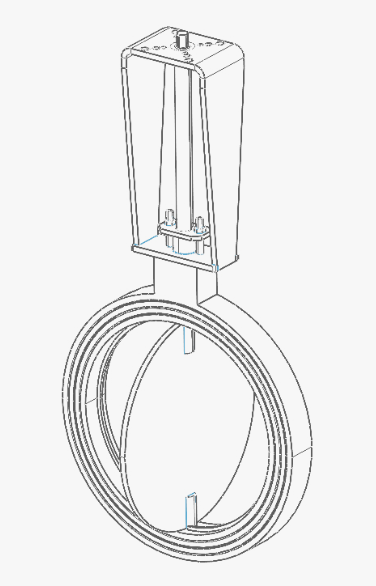

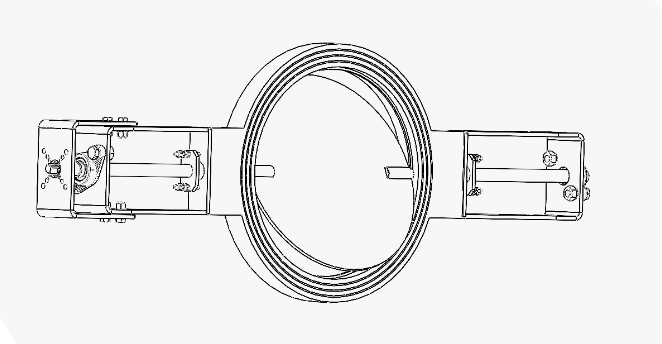

Chalwyn spark arrestors are the quenching type as defined in BS EN 1834-1:2000 clause 5.10.2. In this cyclonic design the glowing particles emitted from a diesel engine exhaust are spun and repeatedly impacted against internal spark arrestor surfaces. This cools them and breaks them down before eventual safe discharge to atmosphere.

Features and Benefits

- Standard Spark Arrestor versions are safe to use where a stray spark from a diesel engine exhaust may ignite surroundings or cause an explosion

- ATEX Spark Arrestor versions are safe to use in potentially explosive atmospheres (the 316L range meets EN 1834 requirements)

- For use as a mandatory requirement globally in the oil and gas industry

- Constructed from corrosion resistant 304L stainless steel or 316L stainless steel for ATEX approved versions, the material is robust providing longevity

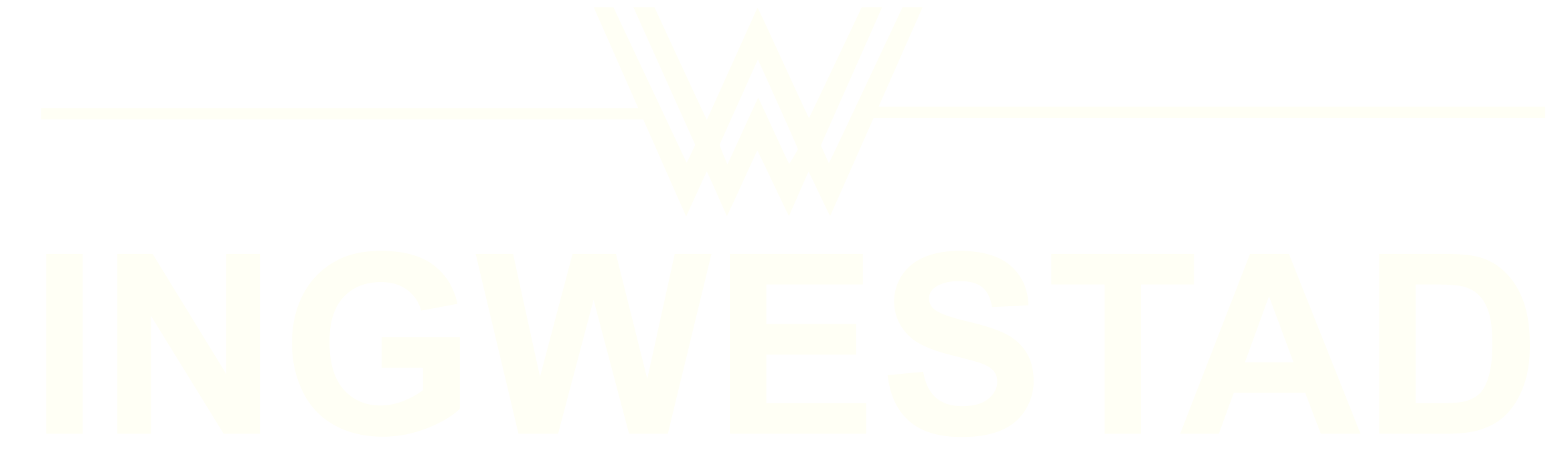

- Wide range of sizes available

- Meets engine manufacturers published back pressure specification providing emission conformance, and exceptional spark-arresting abilities

Exhaust gas flow rates and back pressure limits vary between engine manufacturers. Please consult us with your requirements for further information.

Application

The SSA/SAB Stainless Steel Spark Arrestor is designed for applications where spark emission from a diesel engine exhaust could lead to the ignition of flammable material.

- Oil & Gas Offshore and Onshore

- Refineries

- Gas & LNG Facilities

- Marine

- Mining

Operation

Chalwyn spark arrestors are the quenching type as defined in BS EN 1834-1:2000 clause 5.10.2. In this cyclonic design the glowing particles emitted from a diesel engine exhaust are spun and repeatedly impacted against internal spark arrestor surfaces. This cools them and breaks them down before eventual safe discharge to atmosphere.

NOTE: Traditional forestry approved carbon steel spark arrectors (i.e. USFS) are not designed to be used in a hazardous environment where hydrocarbon vapors could be present, and the carbon steel construction rusts when placed near seawater environments.