Temp table

Service parts

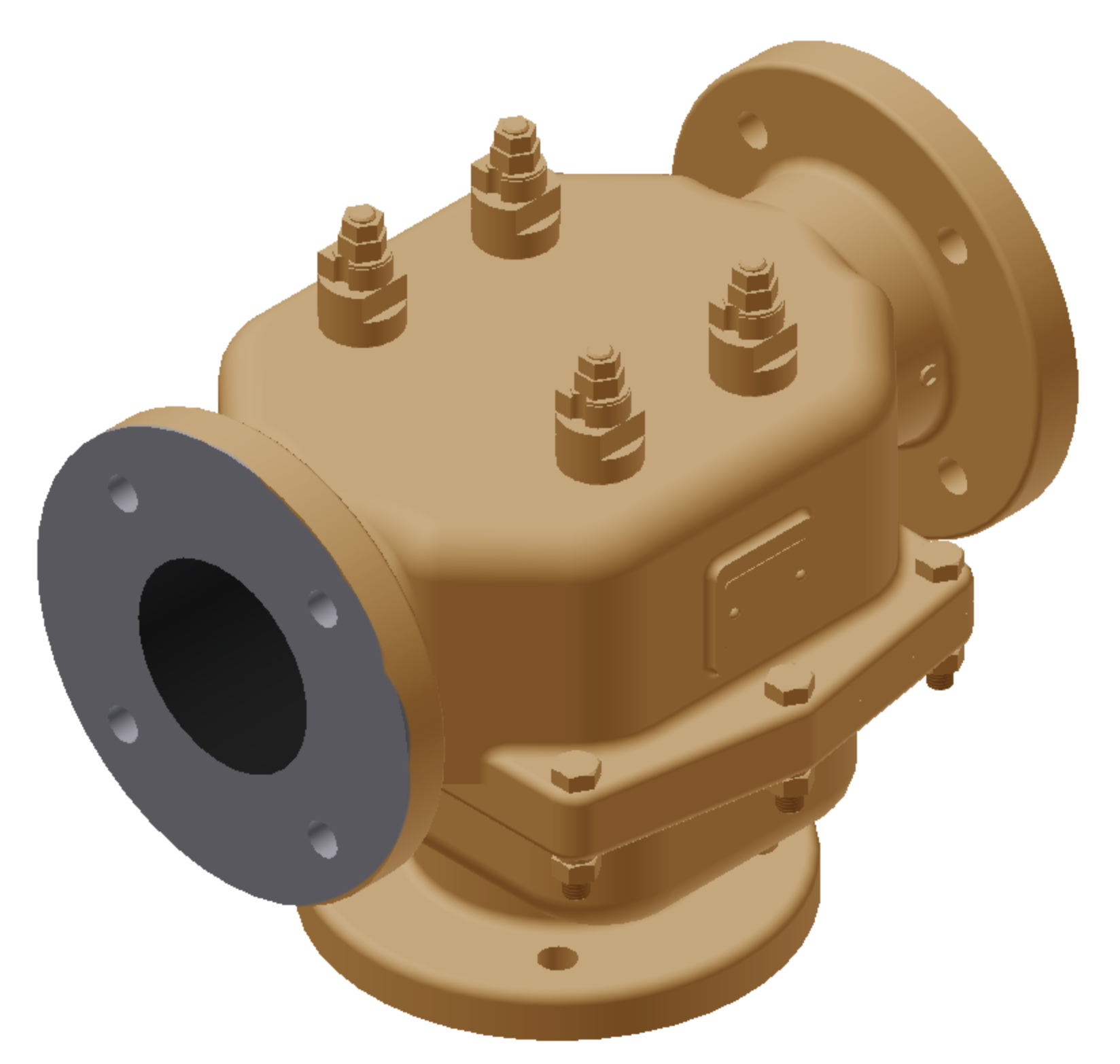

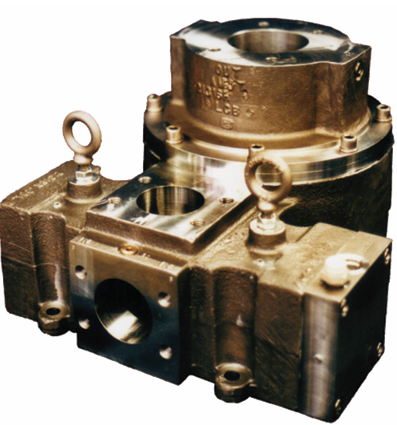

DN100 4500D with flanges

Model 4500D is a 3-way pressure and temperature regulating valve for lubricating oil on gas turbine generator sets. Combined pressure, temperature, and pressure relief in a single valve. Remove downstream pilot pressure regulation. Carbon steel or stainless steel construction. Ports for instrumentation.

The 4500D has been specifically designed and developed by AMOT as a pressure and temperature regulating valve for lubricating oil on gas turbine generator sets. As the oil enters IN Port, the fluid is regulated by the pilot operated cartridge regulator. The pilot feed to the regulator is taken down stream of the filters to sense the oil pressure and connects to Port PP. Pressure is controlled by the dumping of excess oil through the cartridge regulator, which returns back to the main reservoir.

Key features and benefits

• Combined pressure, temperature, and pressure relief in a single valve.

• Remove downstream pilot pressure regulation.

• 4” internally sensed 3-way temperature control valve

• Integrated pressure relief valve

• Reduces installation costs (valves, piping, fittings, flanges)

• Simplifies material planning

• Carbon steel and stainless steel construction

• Ports for instrumentation

Accreditations available

• PED

• ATEX

• Suitable for Group 2 liquids

(Ensure materials are compatible)

II 2G Ex h IIC T6...T3 Gb X

CE: Complies with all relevant EU directives

Maintenance and Service Parts

Unless definite problems are identified during operation, the pressure regulator and temperature element assemblies should be inspected internally every 12 months. It is recommended that seals should be inspected at this stage and replaced if necessary. Should any parts needs to be replaced, please order them using the part numbers and quantities given in the service parts table in the service parts section on page 10. For valve part numbers with Special requirements (E) = -BTJ, -BTU, or BLANK please order the service parts from our Europe and Asia-PAC facilities.

Between maintenance periods on a weekly basis the valve should be wiped over to keep it clean and the paintwork checked for chips and scratches and touched up with good quality paint when necessary to prevent rusting of the external steel parts of the valve.

The valve should also be inspected for any visible signs of leakage and any leaking O-Rings are to be replaced. Before carrying out any maintenance on this valve ensure that an explosive atmosphere is not present. An upgrade kit 48022X is available to convert valves fitted with 1.2 & 1.4 mm orifices to 3 mm.

View datasheet for complete information