Benefits

- High reliability and product lifetime thanks to robust enclosures and modular design

- Easy mounting, wiring and calibration for all common types of valves

- Intelligent diagnostic features (Partial Stroke Test, Fail-in-Place function, Valve Signature, Integrated Pressure Sensors …) for higher plant availability and process security

- Up to 95% lower operating costs due to extreme minimal compressed air consumption

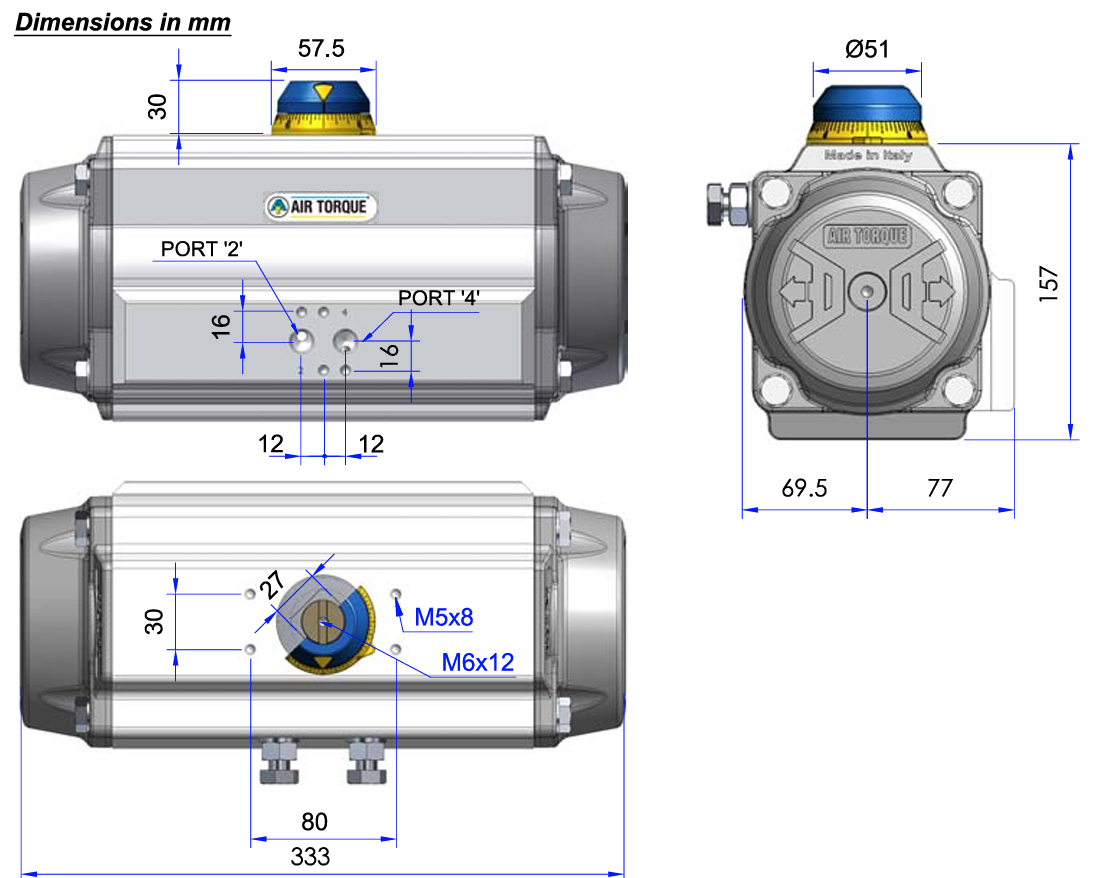

Air Torque pneu actuator with SIEMENS SIPART PS2 postioner

Ing Westad AS stocks Air Torque Pneu Actuator with Siemens Sipart PS2 Positioner, as well as manual override, which together form a complete unit for actuation and control of AMOT´s ACV or other valve that must be turned 0-90 degrees.

The double-acting rack and pinion actuator enables the best control of valves that are not ON/OFF, but must be regulated. Siemens Siepart can be controlled by AMOT´s 8071D and 8072E PIDs. The control signal is 4 - 20 mA IN and OUT. Beyond that, only supply air is needed.It is the standard version we stock, many other configurations can be obtained. Further information follows below.

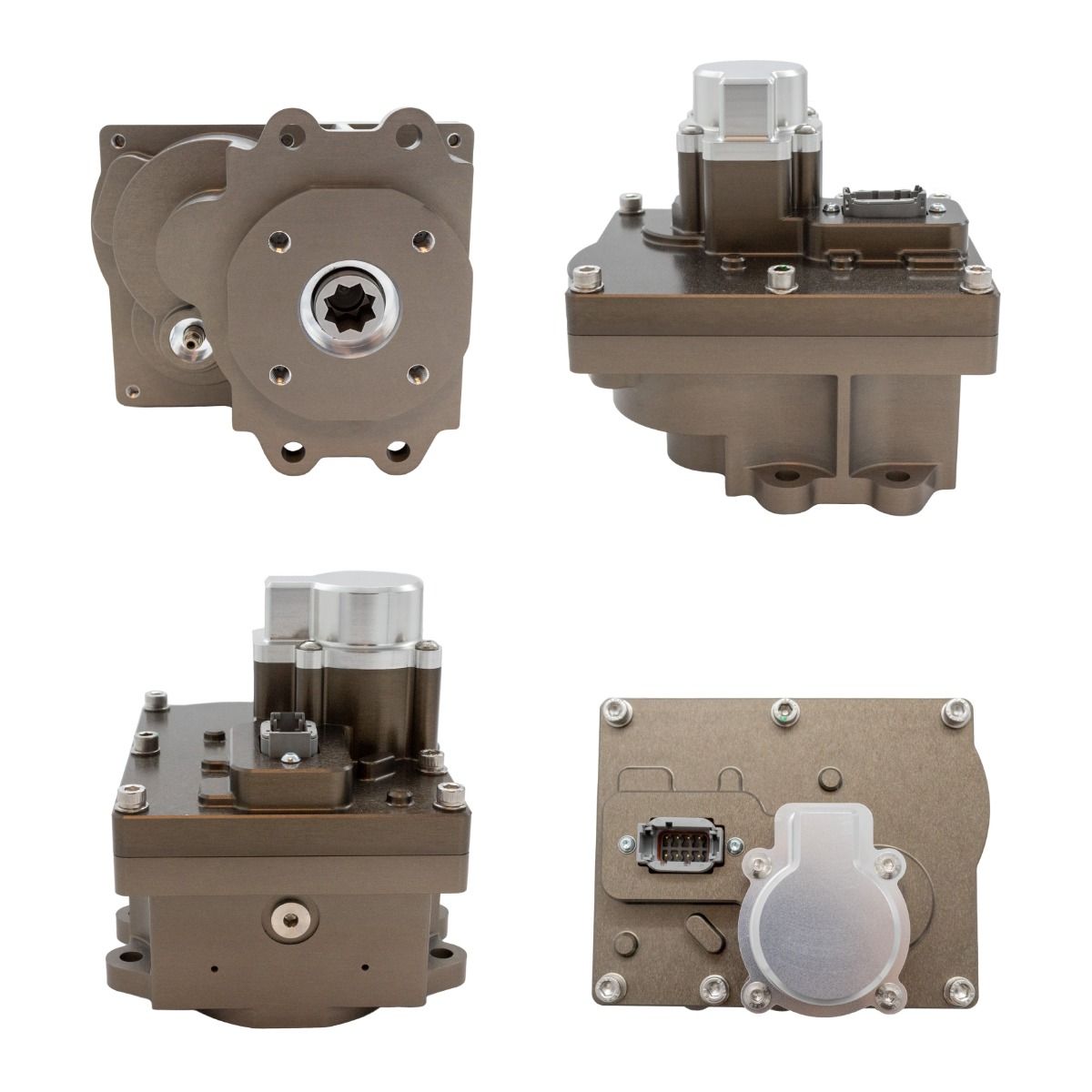

The SIPART PS2 is the most widely used valve positioner for linear and part-turn actuators in industrial applications. The all-round positioner of Siemens provides an extensive range of functions and is well equipped - even for extreme ambient conditions. The following enclosure options are available: Polycarbonate, Aluminum, Stainless steel, Flameproof aluminum or 316L stainless steel.

SIPART PS2 positioners excel in their:

- Easy installation

- Automatic commissioning

- Simple operation and on-device configuration with local display or via SIMATIC PDM

- Very high control performance

- Minimal air consumption in stationary operation

- "Close tight" function for maximum torque on the process valve seat

- "Fast Open/Fast Close" for defined approach of the end position with fast reaction to new setpoint specifications

- "Fail Safe" function: Secure depressurization SIL 2 in case of failure of electrical auxiliary power

- "Fail in place" function: Maintain current position on failure of electrical and/or pneumatic auxiliary power

"Fail to Open" function: Pressurizing of the actuator in case of failure of electrical auxiliary power

Numerous functions can be activated by simple configuring (e.g. characteristic curves and limits)

- One device variant for all applications: Linear actuators, part-turn actuators and cylinders

- Optional with internal or external contactless position feedback for external ambient conditions

- "Intelligent solenoid valve": Solenoid valve function and diagnostics in one device

Extensive diagnostic functions:

- Full Stroke Test

- Multi Step Response Test

- Valve Performance Test

- Valve Signature, pressure sensor-aided

- Partial Stroke Test, optionally pressure sensor-supported for performance and maintenance assessment of the valve

- Leakage monitoring

- Can be operated with natural gas, carbon dioxide, nitrogen or noble gases

- Custom designs for SIPART PS2

- Custom and special functionalities are available after consultation.

DESIGN AND INNOVATION

The 4th Generation Upgrade Series pneumatic actuators, is the result of the Air Torque mission to offer always innovative products by combining the long field experience as market leader, the innovational spirit, the well-known reliability in actuators designing and the high quality manufacturing level. The Air Torque experience has produced the following main key features included in this Series. The 4th Generation Upgrade Series is designed for on/ off and modulating duties.

ROBUST DESIGN

The 4th Generation Upgrade Series is designed and fully tested in the Air Torque facilities according to the latest and most severe international standards. Unique technical features are integrated in this product line to withstand to heavy working conditions and permit to keep the performance level of the actuator stable for long time after the installation. The 4th Generation Upgrade Series is covered by several international patents.

RELIABLE AND FLEXIBLE SOLUTIDNS

By combining high quality products, field and design experience, Air Torque is able to satisfy all the customers and market expectations by offering reliable, flexible and customized solutions together with a qualified service.

INNOVATIVE PATENTE□ DESIGN

The unique technical features developed and incorporated in the 4th Generation Upgrade Series, permits to have the best product versatility for an easier and easier valve automation. The Upgrade Series is covered by several International patents.

TECHNOLOGY AND MATERIAL

The 4th Generation Upgrade Series is manufactured with the highest materials quality, the most accurate materials selections and the latest production technologies.