Actuator

The EA100 actuator with or without positioner is the actuator we primarily recommend. It withstands vibrations and can be mounted in any position, including pointing downwards. Read more about EA100

We can deliver G valve with actuators that meet all requirements, including:

- Operating voltage and control signal, including bus communication.

- Extra vibration-resistant, as well as tolerance to shock.

- Electrical and mechanical failsafe.

- Explosion proof.

- Special surface treatment, incl. NORSOK.

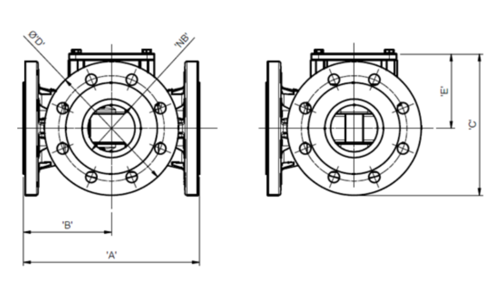

Dimensions

Please see datasheet page 7 for dimensions per valve size.

Control system

Fully programmable PID-based control system allows easy system configuration. Universal inputs; RTD’s, thermocouple, or standard 4-20mA signal gives maximum system design flexibility. Can be operated in manual mode, easy maintenance and set up. Read more about control system

About model codes

Page 20 of the datasheet shows how the model code is structured. Below are examples of model code for the standard version.

Model codes for standard GG (EA100 without postioner)

Spec; PN10-16, RF, MAX 10 BAR, DUCTILE, MODE 32, 230VAC EL ACT SWITCHED LIVE, MAN.O.RIDE.

- 02GGHDBS32FBAAA-AA

- 02.5GGHDBS32FBAAA-AA

- 03GGSDBS32FBAAA-AA

- 03GGHDBS32FBAAA-AA

- 04GGSDBS32FBAAA-AA

- 04GGHDBS32FBAAA-AA

- 05GGSDBS32FBAAA-AA

- 06GGSDBS32FBAAA-AA

- 06GGHDBS32FBAAA-AA

- 08GGSDBS32FBAAA-AA

- 08GGHDBS32FBAAA-AA

- 10GGSDBS32FBAAA-AA

Model codes for standard GG (EA100 with postioner)

Spec; PN10-16, RF, MAX 10 BAR, DUCTILE, MODE 32, 230VAC EL ACT POSTIONER 4-20mA IN-OUT, MODULATING, MAN.O.RIDE.

- 02GGHDBS32FBBCA-AA

- 02.5GGHDBS32FBBCA-AA

- 03GGSDBS32FBBCA-AA

- 03GGHDBS32FBBCA-AA

- 04GGSDBS32FBBCA-AA

- 04GGHDBS32FBBCA-AA

- 05GGSDBS32FBBCA-AA

- 06GGSDBS32FBBCA-AA

- 06GGHDBS32FBBCA-AA

- 08GGSDBS32FBBCA-AA

- 08GGHDBS32FBBCA-AA

- 10GGSDBS32FBBCA-AA

AMOT GG Low Leakage Valve

GG valves are 3-way temperature control valves consisting of a powerful rotary valve and either a modulating EL or PNEU actuator.

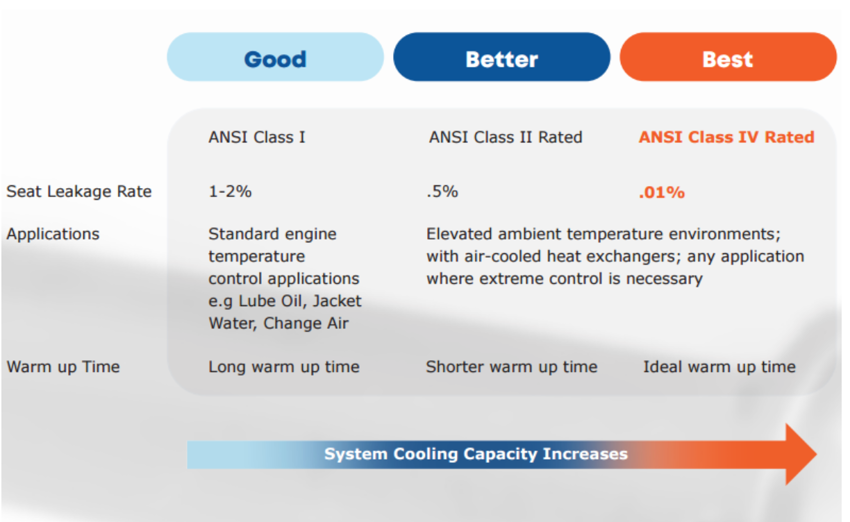

The GG model is AMOT´s newest and most modern model, which over time will replace all older models such as GEF and GPD. GG standard design is made for coolants in fresh water/glycol or oil, for system pressure up to 10 bar, design max temp 100ﹾC and max flow 770 m3/h. See model GEF/GPD for flow > 770 m3/h. Model G valve, the Low Leak valve eliminates bypass leakage, increases cooling capacity, and ecreases fuel consumption. This low leak valve maximizes engine performance and is ideal for applications where air cooled heat exchangers are used. The GG version for low leakage is supplied in two versions. One that meets ANSI Class III, rated leakage of up to 0.5%. Furthermore, there is a version that meets ANSI Class IV, rated leakage 0.01%.

CASE STUDY Rigorous testing ensures quality and quantifies benefits

AMOT conducted field trials on engines in high-ambient-temperature environments. According to one engine manufacturer, the LT circuit needs to maintain a temperature of 45° C for maximum fuel efficiency. The ambient temperature in the test environment averages between 40-45°C. The low leak valve installed easily, replacing the existing valve without the need for pipe modifications. Data was collected on engines using the low leak valve vs. other temperature control valves. After more than 5,000 hours of continuous operation, the low leak valve proved its durability, reliability, and cost savings. Results from the engine using the low leak valve showed an engine inlet temperature from the cooler of 4° C less than other control valves. Depending on fuel costs, this could potentially lead to a return on investment within 6 months.

- Large selection of sizes and materials.

- Flexible port configuration.

- Can be mounted in any direction, including with the actuator pointing downwards.

- Large flow, low pressure drop.

- Small physical size.

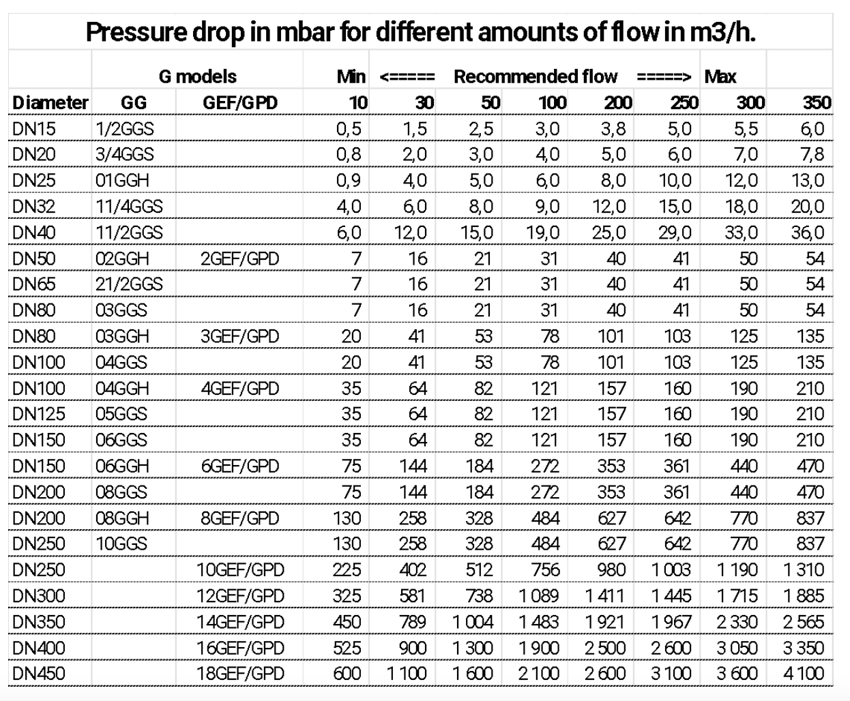

Sizes

The table below shows available sizes in inches and mm, as well as pressure drop in mbar for different amount of flow in m3/h. AMOT G valves are designed to produce minimal pressure drop. The normal recommendation in sizing the valves is to select a pressure drop between 25 - 300 mbar. The normal recommendation for salt water in bronze valves is a max pressure drop at 100 mbar.

See datasheet for pressure drop values for oil and other fluids with higher viscosity.

Flanges

EN1092: PN6, PN10 and PN16.

ASME: 125, 150, 300 and 600lb.

JIS: 5 and 10K.

Max pressure is 10 barg, unless otherwise stated, regardless of flange type.

View datasheet for complete information