Actuator

The EA100 actuator with or without positioner is the actuator we primarily recommend. It withstands vibrations and can be mounted in any position, including pointing downwards. Read more about EA100 (link to EA100). We can deliver G valve with actuators that meet all requirements, including:

- Operating voltage and control signal, including bus communication.

- Extra vibration-resistant, as well as tolerance to shock.

- Electrical or mechanical failsafe.

- Explosion proof.

- Special surface treatment, incl. NORSOK.

Dimensions

Please see datasheet page 7 for dimensions per valve size. View datasheet

Control system

Fully programmable PID-based control system allows easy system configuration. Universal inputs; RTD’s, thermocouple, or standard 4-20mA signal gives maximum system design flexibility. Can be operated in manual mode, easy maintenance and set up. Read more about control system

About model codes

Page 20 of the datasheet shows how the model code is structured. Below are examples of model code for the standard version.

Model codes for standard GG (EA100 without postioner)

Spec; PN10-16, RF, MAX 10 BAR, DUCTILE, MODE 32, 230VAC EL ACT SWITCHED LIVE, MAN.O.RIDE.

- 02GGHDBS32FBAAA-AA

- 02.5GGHDBS32FBAAA-AA

- 03GGSDBS32FBAAA-AA

- 03GGHDBS32FBAAA-AA

- 04GGSDBS32FBAAA-AA

- 04GGHDBS32FBAAA-AA

- 05GGSDBS32FBAAA-AA

- 06GGSDBS32FBAAA-AA

- 06GGHDBS32FBAAA-AA

- 08GGSDBS32FBAAA-AA

- 08GGHDBS32FBAAA-AA

- 10GGSDBS32FBAAA-AA

Model codes for standard GG (EA100 with postioner)

Spec; PN10-16, RF, MAX 10 BAR, DUCTILE, MODE 32, 230VAC EL ACT POSTIONER 4-20mA IN-OUT, MODULATING, MAN.O.RIDE.

- 02GGHDBS32FBBCA-AA

- 02.5GGHDBS32FBBCA-AA

- 03GGSDBS32FBBCA-AA

- 03GGHDBS32FBBCA-AA

- 04GGSDBS32FBBCA-AA

- 04GGHDBS32FBBCA-AA

- 05GGSDBS32FBBCA-AA

- 06GGSDBS32FBBCA-AA

- 06GGHDBS32FBBCA-AA

- 08GGSDBS32FBBCA-AA

- 08GGHDBS32FBBCA-AA

- 10GGSDBS32FBBCA-AA

- Features and Benefits: Ease of integration - valve size matches pipe size, resulting in reduced installation time and installation costs * Flexible design - ports can be configured to suit installation * Low pressure drop - compared to other valve types * Small physical size * Hand wheel allows manual adjustment of valve (optional on pneumatic valve) * Simplified set up and maintenance

- Typical applications : For engines, turbines, gearboxes and heat exchangers: * Charge air cooling * Secondary cooling systems * Fuel and lube oil preheating * Co-generation * Engine jacket water For refineries, chemical plants and oil reproduction: * Waste heat boilers * Product coolers * Product heaters * Product condensers

GG Standard design 3-way valves for temperature regulation

GG valves are 3-way temperature control valves consisting of a powerful rotary valve and either a modulating EL or PNEU actuator.

The GG model is AMOT´s newest and most modern model, which over time will replace all older models such as GEF and GPD. GG standard design is made for coolants in fresh water/glycol or oil, for system pressure up to 10 bar, design max temp 100ﹾC and max flow 770 m3/h. See model GEF/GPD for flow > 770 m3/h.

- Large selection of sizes and materials.

- Flexible port configuration.

- Can be mounted in any direction, including with the actuator pointing downwards.

- Large flow, low pressure drop.

- Small physical size.

Sizes

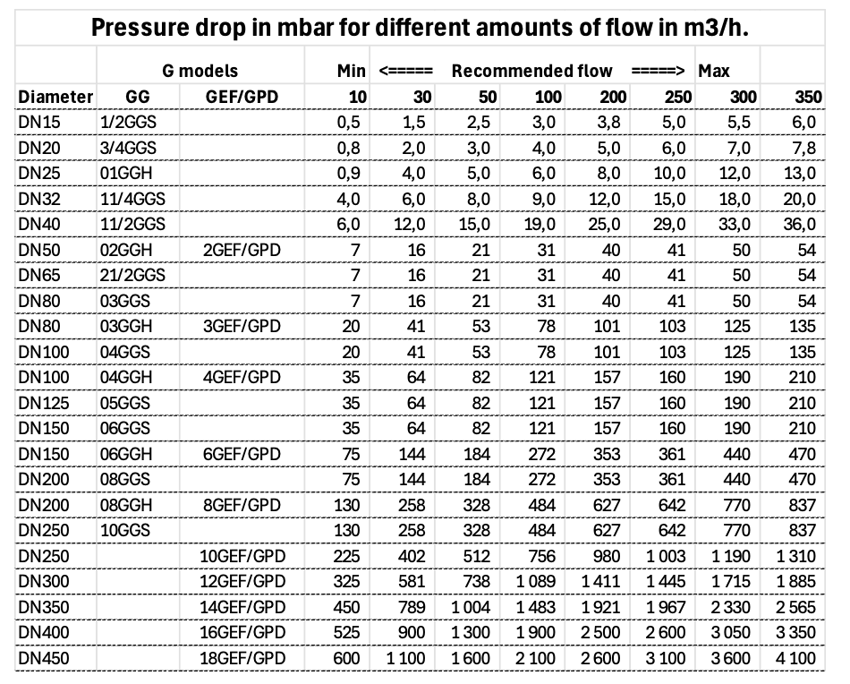

The table below shows available sizes in inches and mm, as well as pressure drop in mbar for different amount of flow in m3/h. AMOT G valves are designed to produce minimal pressure drop. The normal recommendation in sizing the valves is to select a pressure drop between 25 - 300 mbar. The normal recommendation for salt water in bronze valves is a max pressure drop at 100 mbar. See datasheet for pressure drop values for oil and other fluids with higher viscosity.

Flanges

EN1092: PN6, PN10 and PN16.

ASME: 125, 150, 300 and 600lb.

JIS: 5 and 10K.

Max pressure is 10 barg, unless otherwise stated, regardless of flange type.

View datasheet for complete information